Fatty acid methyl ester, FAME, is a nontoxic, biodegradable biodiesel that can be produced from a wide array of vegetable oils and fats. It is used both as a drop-in component in fossil diesel and as a pure fuel. It is then called B100 (see f3 2017). In 2022, FAME, together with bioethanol, was the leading renewable liquid fuel on a global basis, positions that are expected to last at least until 2028 (IEA 2023). In Sweden, FAME was the second largest renewable liquid fuel on the market in 2023, representing 3.7 TWh, however significantly smaller than HVO (16.7 TWh)). Historically, rapeseed oil has been the primary raw material for FAME produced and used in Sweden, but in recent years small amounts of used cooking oil and animal fats are sources for FAME on the Swedish market (Energimyndigheten 2025).

Primary area of use

Fatty acid methyl ester, FAME, commonly biodiesel, is used as fuel in diesel engine vehicles. Normally, it is a blend component in conventional fossil diesel, but it can also be used as stand-alone fuel for heavy-duty vehicles. The Swedish standard SS 15 54 35:2022 allows up to 7% v/v of FAME in diesel fuel without any modifications in vehicles or the distribution system, while driving on pure FAME (B100) is conditioned by an approval from the vehicle manufacturer to ensure compatibility of materials and engine settings (Drivkraft Sverige 2025).

European FAME is fully miscible with fossil diesel and apart from increasing the renewable content, it improves the lubricating properties. However, FAME is sensitive to cold climate and different grades are therefore sold depending on the climate zone of the distribution area (Drivkraft Sverige 2024). In addition, FAME is biodegradable and prone to oxidation, and it is recommended not to store FAME and FAME-blended diesel for more than one year (Drivkraft Sverige 2025).

FAME can also be used as a pure fuel, called B100. Today, several trucks, busses and light transportation vehicles have been approved for the use of pure FAME. In Sweden the market for B100 has varied over time, with peaks at about 1.5 TWh in 2015 and 2019 and drops to below 0.5 TWh in 2017 and 2021 (Energimyndigheten 2025). B100 can be used down to about -15 °C without risking that it precipitates (Drivkraft Sverige 2025).

Distribution system

FAME is a liquid fuel and does not require any modification to the distribution systems when blended into fossil diesel. In 2024, the share of FAME in diesel was about 2.1% (Drivkraft Sverige 2025). Pure FAME is no longer available at public filling stations (Miljöbarometern 2025). However, it is still distributed to fleets.

Feedstock and production

FAME can be produced from a wide array of oils and fats. In Europe in 2022, the most common feedstocks for FAME and HVO together were rapeseed (40%) and palm oil (26%). The share of palm oil is gradually decreasing in anticipation of the end of the phase-out foreseen in the EU Delegated Act on High ILUC, while the share of feedstocks for advanced biofuels is increasing. In Europe in 2022, the shares of sunflower oil and soybean oil were very limited. In the United States, soybean oil is the primary feedstock, accounting for around 50% of biodiesel production. In Asia, particularly in Indonesia and Malaysia, palm oil is the primary feedstock for biodiesel production (EBB 2023).

Generally, FAME can be produced from any fatty acid source, meaning that algae, jatropha, animal fats and other waste oils can be used. However, the fatty acid composition of the feedstock determines the properties of the final product. Generally, unsaturated and polyunsaturated fatty acids have low melting points. On the other hand, too much polyunsaturated fatty acids increase the oxidation tendency and hence shortens the storage time of the fuel. Therefore, climate zone, required filterability, etc. must be considered in the choice of feedstock or feedstock mix. In comparison to other feedstocks, rape seed oil has advantageous properties in cold climate (Drivkraft Sverige 2025).

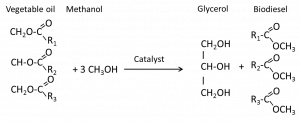

FAME is produced through transesterification of fatty acids and methanol. Oil and fat consist of triglycerides that separate to form FAME and glycerol in a transesterification process by replacing the glycerol-backbone in the triglyceride with an alcohol, typically methanol, under the action of a catalyst (i.e. sodium hydroxide). The triglycerides and methanol then form straight-chain methyl esters that are separated and purified in several steps to meet the fuel specification. The methanol used in the production is typically of fossil origin, but it can also be produced from renewable raw materials. Glycerol is a byproduct from the biodiesel process and depending on its purity, it is sold in different market segments.

The transesterification reaction for producing FAME from vegetable oil.

Current production and use as fuel

The consumed FAME in Sweden during 2023 corresponded to 3.7 GWh, which represented 33% of the energy in liquid renewable fuels on the market (HVO, FAME and bioethanol) (Energimyndigheten 2025). Out of this, low blended FAME and high blended FAME represented 1.8% (2,6 TWh) and 0.8% (1.2 TWh), respectively, of the energy content in liquid biofuels (Drivkraft Sverige 2025). The shares of consumption of different biofuels, as well as the total consumption of biofuels, varies with policy, such as the Swedish reduction quotas that were reduced in 2023 (f3 2023).

To fulfil the demand of the Swedish FAME producers, more than 95% of the feedstock in the FAME produced in Sweden was imported in 2023 (Miljöbarometern 2025). The European Union is the largest producer of FAME globally with a production of roughly 13.7 million tonnes (corresponding to 145 TWh) in 2022 which corresponds to about 25% of the global output (EBB 2023). Germany, France, Italy and Spain are the main producers, where the production of biofuels is supported by national policies and incentives (e.g. blending mandates and tax exemptions) and by the Renewable Energy Directive (Biofuels News 2023). The EU is followed by the US, which had a production of 10.2 million tonnes in 2022. Indonesia and Brazil are the third and fourth largest biodiesel producers, with a production reaching 9.7 million tonnes and 5.4 million tonnes respectively (EBB 2023). Many companies involved in the production of biofuels are also players in the conventional fossil energy business. Hence, it is not possible to allocate the value chain of those companies exclusively to biofuels production (Motola et al 2023).

In Sweden there are two main production sites of RME, the rape seed-based FAME: Adesso Bioproducts in Stenungsund, producing roughly 120 000 tonnes RME per year and Ecobränsle in Karlshamn with a production capacity of almost 50 000 tonnes RME per year, together corresponding to about 1.8 TWh. Since the Swedish consumption of FAME in 2023 was 3.7 GWh, FAME produced in Sweden is exported. There are also many small Swedish production sites, for example Tolefors Gård in Östergötland that produces roughly 350 tonnes RME per year from used cooking oil.

FAME projects

There are plans to double the production capacity at the RME facility in Karlshamn (Bioenergitidningen 2022). However, according to a partowner, the timeplan is unclear (E. Jacobsson, personal communication, 24 March 2025).

A small facility of Ernsts Express in Avesta, that was intended for production of RME based on mixed used oils and fats and started operating in 2019 (BiodrivMitt 2019), is currently on hold. However, it would be used within an EU project during 2025, running on turnip rapeseed oil (Margin-Up 2023).

Download factsheet

FAME - Fatty acid methyl estersProperties

Chemical formula: CH3(CH2)nCOOCH3 (General formula of methyl esters)

Molecular mass: RME: 296g/mol (Oleic acid C18:1)

Density at 15°C 1,013 bar: 860-900 kg/m³

Heating value: RME: 38 MJ/kg

Cetane number: > 51