Recent articles and statements in the media [1, 2] raise concerns over the climate effects of using forest biomass for…

Recent articles and statements in the media [1, 2] raise concerns over the climate effects of using forest biomass for bioenergy. As some statements seem to reflect misconceptions about forest bioenergy, IEA Bioenergy here provides a brief overview of key facts about the use of forest biomass for climate change mitigation. [3]

This fact sheet reproduces a text developed by Göran Berndes, Annette Cowie, Luc Pelkmans and members of IEA Bioenergy Task 45, the IEA Bioenergy Technology Collaboration Programme (TCP). f3 publishes the text as a whole with permission from IEA Bioenergy.

This fact sheet reproduces a text developed by Göran Berndes, Annette Cowie, Luc Pelkmans and members of IEA Bioenergy Task 45, the IEA Bioenergy Technology Collaboration Programme (TCP). f3 publishes the text as a whole with permission from IEA Bioenergy.

The IEA Bioenergy TCP is organised under the auspices of the International Energy Agency (IEA) but is functionally and legally autonomous. Views, findings and publications of the IEA Bioenergy TCP do not necessarily represent the views or policies of the IEA Secretariat or its individual member countries.

In summary

Energy from woody biomass can contribute to climate change mitigation, as a renewable fuel. It should be used efficiently, and when harvested from forests, it must come from sustainably managed forests, where carbon stocks are maintained or enhanced on a regional or national basis. Forest bioenergy can support rapid transformation of the energy sector. Furthermore, bioenergy linked with carbon capture and storage (BECCS) is one of the options that can deliver negative emissions, likely to be required to meet the temperature targets of the Paris Agreement. Forest management that maintains or increases carbon stocks, while also producing timber, fibre and energy, contributes to climate change mitigation by storing carbon on land and replacing carbon-intensive materials and fossil fuels.

1. Forest bioenergy is not by definition carbon neutral; emissions in the supply chain and impacts on forest carbon stock must be included.

Bioenergy is sometimes said to be “carbon neutral” in the sense that the carbon that is released during combustion (biogenic carbon emissions) has previously been sequestered from the atmosphere and will be sequestered again as the plants regrow.

But “carbon neutrality” is an unhelpful term because it is ambiguous and used differently in different contexts. As is further elaborated below, biogenic carbon needs to be considered in assessments in order to fully reflect how bioenergy will affect atmospheric GHG concentrations. If extraction of biomass for energy leads to a decline in the forest carbon stock or carbon sink strength, this needs to be accounted for. Furthermore, assessments need to consider all emissions associated with the production, processing, transport and use of bioenergy. Finally, the bioenergy scenario should be compared with a counterfactual scenario, in which energy is provided by another source, to quantify the net effect on GHG emissions.

2. Forest biomass is not treated as carbon neutral in national greenhouse gas inventories.

The treatment of bioenergy in greenhouse gas inventories has been criticized for containing a loophole because bioenergy is “counted as carbon neutral”. This is incorrect. Under the agreed approach for preparation of national greenhouse gas inventories, countries report harvest of forests for any purpose, including bioenergy, as a CO2 emission in the land use sector. [4] CO2 emissions from combustion of biomass for energy are not counted in the energy sector to avoid double counting with the land use sector. Thus, there is no accounting error that requires correction, or emission that is overlooked in reporting, and bioenergy is not assumed to be carbon neutral: if bioenergy leads to a reduction (or slower growth) in forest carbon stock this is reflected in national inventories. [5] Fuel use in the supply chain is counted in the energy sector of the country where the fuel is consumed, as for all other traded materials including energy carriers.

Where biomass for bioenergy is traded, the importing country reports no emissions, while the exporting country reports the emissions in the land sector. This convention could be criticised as supporting “outsourcing” of emissions by the importing country. This issue applies also to off-shore manufacturing. For instance, a large share of emissions associated with production of goods consumed in Europe is reported by China, where manufacturing occurs. [6] The case of biomass imports for bioenergy is an example where policymakers have recognized and taken action to address this challenge. [7] The EU RED II requires that forest biomass is sourced only from locations where legislation at national/subnational level, or management systems at the forest sourcing area, ensure that forests are regenerated and that carbon stocks and sink levels in the forest are maintained or strengthened over the long term. [8] Specifically concerning EU pellet importation from the United States, data show that forest carbon stocks in the south-eastern United States (SE US) where biomass is sourced, are steadily increasing, [9 ] and biomass harvests for wood pellets represent only a small fraction of harvest removals from forests in the SE US. [10]

3. Climate effects of using woody biomass cannot be determined at stand level; assessments need to be made at the landscape (estate) level.

A forest estate is generally managed as a series of stands of different ages, harvested at different times, to produce a constant supply of wood products. When considered at stand level, much of the carbon that has been sequestered into the stand as the trees grow is abruptly lost from the stand at the time of harvest, and is not fully sequestered again until the stand has reached harvest age. Stand-level assessments that start the accounting when the stand is harvested will, therefore, show upfront emissions and a delay before forest bioenergy contributes to net reductions in atmospheric CO2, particularly in long-rotation forests.

However, across the whole forest estate (landscape), i.e., at the scale that forests are managed, carbon losses in harvested stands are balanced by carbon gains (growth) in other stands, so the carbon stock of production forests is roughly stable. The magnitude of the carbon stocks in forest landscapes depends on biophysical factors such as soil and climate conditions, historic and current management regimes, and events such as storms, fires and insect outbreaks. To quantify the climate effects of harvesting woody biomass for energy and other products, the effect of this harvesting on the development of carbon stocks at the landscape level needs to be determined.

Landscape-scale assessment can provide a more complete representation of the dynamics of forest systems, as it integrates the effects of all changes in forest management and harvesting that take place in response to – experienced or anticipated – bioenergy demand. The landscape approach therefore helps to identify how total forest carbon stocks are affected by specific changes in forest management. For instance, if a new management regime with more residues and/or trees extracted, or a shorter rotation length, leads to a long-term decline in the carbon stock and carbon sink capacity of the forest estate, this would reduce the climate benefit. On the other hand, an increase in demand for bioenergy and other forest products could also incentivise changes in forest management (e.g., improved site preparation, use of nurse trees, advanced genetics, measures to reduce risks for forest fires or pests/diseases) that enhance forest sink strength and carbon stocks.

4. Forest biomass is a renewable energy source if forest productivity is maintained.

Forest biomass is renewable if it is harvested from forests that are managed such that there is no loss of productive capacity – i.e., so that growth rate and therefore capacity to sequester carbon are maintained over successive rotations. Sustainable forest management is key to maintaining healthy and productive forests. Biomass derived from deforestation should not be recognized as renewable.

5. The climate change effect of using biomass for energy cannot be determined by comparing GHG emissions at the point of combustion.

It is sometimes stated that CO2 stack emissions per MWh inevitably increase when biomass replaces coal. However, at the point of combustion, wood and coal have similar CO2 emission factors, as the ratio of heating values between the two fuels is similar to the ratio of carbon content. Furthermore, biomass fuel characteristics (moisture content, grindability, heating value) affect the energy efficiency of co-firing systems. In large coal power plants, there can be a derating of a few percent, as there is more flue gas generated per GJ of fuel, which leaves the stack at a temperature above the ambient temperature resulting in so-called stack losses. However, when the co-firing ratio is low (<10%) there is usually no significant efficiency penalty. Fuel type (both coal and biomass) also matters. For low rank coal, biomass co-firing (especially torrefied biomass) can increase the boiler efficiency and net power plant efficiency. The outcome also depends on modifications made when power plants are adapted to using biomass (e.g., investments in steam turbine upgrades and internal waste heat utilization to dry biomass fuel).

More importantly, comparing emissions at the point of combustion does not show the effect on atmospheric GHG concentrations of switching from fossil fuels to biomass. There is a fundamental difference between fossil fuels and biomass: burning fossil fuels releases carbon that has been locked up in the ground for millions of years, while burning biomass emits carbon that is part of the biogenic carbon cycle. In other words, fossil fuel use increases the total amount of carbon in the biosphere-atmosphere system, while bioenergy systems operate within this system; if the forest carbon stock is constant there is no net transfer of carbon to the atmosphere.

Instead of comparing GHG emissions at the point of combustion, the biogenic carbon flows and fossil GHG emissions associated with the complete life cycle of the bioenergy system need to be compared with the GHG emissions in a realistic reference situation (counterfactual scenario) where energy sources other than bioenergy are used. Also, indirect impacts (positive or negative) on land use, wood products and fossil fuel use need to be considered.

6. Long-distance transport does not negate the climate benefits of woody biomass as a renewable energy source.

Fossil energy used in the biomass supply chain is generally small compared to the energy content of the bioenergy product, even when transported internationally. For example, the fossil fuel use related to cultivation and processing of wood pellets corresponds to between 2.5 and 15 g CO2/MJ. [11] Transporting pellets between North America and Europe increases supply chain emissions by up to 5 g CO2/MJ [12] (for comparison: the life cycle GHG emissions of hard coal (supply & combustion) is around 112 g CO2/MJ). Thus, long-distance transport does not negate the climate benefits of forest-based bioenergy; these supply chains still offer substantial climate benefit when sourced from sustainable biomass.

7. Switching from coal to woody biomass reduces atmospheric CO2 over time scales relevant to climate stabilisation.

Some articles point to the fact that forest-based bioenergy systems can cause a short-term increase in emissions, although delivering mitigation in the longer term, and claim that bioenergy is not compatible with climate change goals if it has a payback period of more than a decade, due to the urgent need to address climate change.

First, there remains disagreement about the appropriate methodological approach for calculating payback time. Stand-level assessments are in our view not appropriate since they represent the assessed system as a strict sequence of events (e.g., site preparation, planting or natural regeneration, thinning and other silvicultural operations, final felling) that in reality occur simultaneously0 across the forest landscape (see point 3). The outcome for stand-level assessments will vary dramatically for the same system, depending on which starting point is chosen (time of replanting or time of harvest). Moreover, defining a realistic counterfactual for the calculation of payback times is critical, but challenging, considering the dynamics of forestry systems. Some studies use unrealistic assumptions for counterfactuals, e.g. assuming that forests planted for commercial use are left unharvested when there is no demand for bioenergy, and ignoring that most forest biomass used for bioenergy is a by-product of high value timber.

Second, the relationship between net emissions, global warming and climate stabilisation is complex. The IPCC 1.5 report [13] shows many alternative trajectories towards stabilization temperatures of 1.5 and 2°C. The IPCC emphasizes the need for transformation of all the major sectors of society to achieve net zero CO2 emissions, and finds a requirement for carbon dioxide removal in many scenarios. The IPCC’s assessment of current scientific understanding does not conclude that individual measures towards achieving transformation need to meet specific “payback periods”.

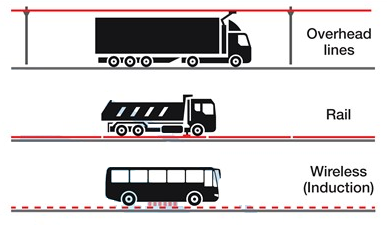

The most important climate change mitigation measure is to transform energy and transport systems so that we can leave fossil carbon in the ground. Using bioenergy now, in conjunction with other renewables, is an important measure to achieve this. Biomass is a storable, dispatchable energy source that can support the rapid expansion of intermittent renewables, providing grid stability and balancing. In the longer term, biomass is likely to be primarily used in applications where the substitution of carbon-based fuels is particularly difficult, such as in aviation and long-distance marine transportation. Biomass may also be increasingly used in applications that deliver net negative GHG emissions. For the mid – to longer term, the IPCC 1.5 report found most scenarios that deliver climate stabilisation at 1.5 or 2°C require substantial deployment of negative emissions technologies. Bioenergy linked with carbon capture and storage (BECCS) is one of the major available options for achieving negative emissions. The further transformation of existing power systems will depend on how biobased and other technologies develop to meet future demands, including the development of technologies for providing negative emissions that are not based on biomass.

Concern about near-term emissions is not a strong argument for stopping investments that contribute to net emissions reduction beyond 2030, be it the scaling-up of battery manufacturing to support electrification of car fleets, the development of rail infrastructure, or the development of biomass supply systems and innovation to provide biobased products displacing fossil fuels, cement and other GHG-intensive products. We assert that it is critical to focus on the global emissions trajectory required to achieve climate stabilization, acknowledging possible trade-offs between short- and long-term emissions reduction objectives. A strong focus on short-term carbon balances may result in decisions that make long-term climate objectives more difficult to meet.

8. Sustainability governance is required to ensure that woody biomass used for energy makes a positive contribution to addressing climate change and other societal goals.

Scientific studies have shown that forest-based bioenergy can make a substantial contribution to climate stabilisation. Sustainability governance is needed to support achievement of this potential and minimise the risk of negative outcomes. Many countries have rigorous forest management regulations requiring implementation of sustainable forest management practices. [14] Sustainable forest management, such as defined by FSC- or PEFC-endorsed schemes, is used to manage hundreds of millions of hectares of forest worldwide, and these practices should be deployed more broadly. Sustainability requirements have been developed to govern the eligibility of forest biomass for renewable energy in several countries as well as under the updated European Renewable Energy Directive. Regulations governing eligibility for bioenergy subsidies in the Netherlands, for example, stipulate that natural forests cannot be converted, that biodiversity and forest vitality are at least maintained, that forests must be regrown, and that forest carbon stock must be maintained or increased in the long term. To secure sustainability compliance and oversight throughout the chain, all economic operators are supervised by public authorities and the certification schemes involved.

9. Managed forests can provide greater climate benefits than conservation forests.

The cessation of harvesting from forests, to allow them to sequester carbon, has been proposed as a climate change mitigation option that also can provide other benefits such as biodiversity protection. There are indeed many good reasons for protecting natural forests. With respect to climate, the IPCC has pointed out that forests managed for producing sawn timber, bioenergy and other wood products can make a greater contribution to climate change mitigation than forests managed for conservation alone. This is for three reasons. First, the sink strength diminishes as conservation forests approach maturity; production forests maintained in an actively growing state have high sink strength. Second, wood products displace GHG-intensive materials and fossil fuels. Third, carbon in forests is vulnerable to loss through natural events such as insect infestations or wildfires, as recently seen in many parts of the world including Australia and north America. Managing forests can help to increase the total amount of carbon sequestered in the forest and wood products carbon pools, reduce the risk of loss of sequestered forest carbon, and reduce fossil fuel use.

10. Managed forests produce wood for multiple products, not just bioenergy.

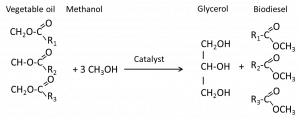

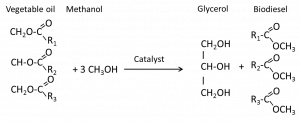

The picture, which is often presented, that whole forest stands are cut for bioenergy alone, is misleading. Forest biomass for bioenergy is typically obtained from forests managed for multiple purposes, including production of pulp and saw logs, and provision of other ecosystem services (e.g., air quality improvement, water purification, soil stabilization, biodiversity conservation). Bioenergy systems are components in value chains or processes that aim to produce forest products such as sawnwood, paper and chemicals. Stems that meet quality requirements are used to produce high value products such as sawnwood and wood panels, displacing carbon-intensive building materials such as concrete, steel and aluminium, while residues from forestry operations (tops, branches, thinnings, wood that is unsuitable for lumber) and wood processing residues are used for bioenergy. (e.g. [15]). When bioenergy from forest biomass displaces fossil fuels, this adds to the climate benefits of managed forestry.

Footnotes

- For example: BBC News 23.02.2017 “Most energy schemes are a ‘disaster’ for climate change”; EASAC press release 10.09.2019 “EASAC’s Environmental Experts call for international action to restrict climate-damaging forest bioenergy schemes”; The Guardian 16.12.2019 “Converting coal plants to biomass could fuel climate crisis, scientists warn”; EASAC press release 26.08.2020 “Emissions Trading System: Stop Perverse Climate Impact of Biomass by Radically Reforming CO2 Accounting Rules”

- For example: Brack, D., 2017. Woody biomass for power and heat: Impacts on the global climate. Environment, Energy and Resources Department, Chatham House.; Searchinger, T.D., Beringer, T., Holtsmark, B., Kammen, D.M., Lambin, E.F., Lucht, W., Raven, P. and van Ypersele, J.P., 2018. Europe’s renewable energy directive poised to harm global forests. Nature communications, 9(1), pp.1-4.; Sterman, J.D., et al., 2018. Does replacing coal with wood lower CO2 emissions? Dynamic lifecycle analysis of wood bioenergy. Environmental Research Letters, 13(1), p.015007.; Norton, M.et al., 2019. Serious mismatches continue between science and policy in forest bioenergy. GCB Bioenergy, 11(11), pp.1256-1263.

- IEA Bioenergy, 2020. The use of forest biomass for climate change mitigation: dispelling some misconceptions. https://www.ieabioenergy.com/wp-content/uploads/2020/08/The-use-of-biomass-for-climate-change-mitigation-dispelling-some-misconceptions-August-2020-Rev1.pdf

- UNFCCC reporting sectors Agriculture, Forestry and Other Land Use (AFOLU), formerly Land use, Land-use change and Forestry (LULUCF) sector.

- However, there is incomplete coverage under the Kyoto Protocol because only some countries account for their GHG emissions in the second (2013- 2020) commitment period. Under the Paris Agreement, commencing 2020, all parties will include the land sector in their national accounting.

- E.g. Chen, Q., Löschel, A., Pei, J., Peters, G.P., Xue, J. and Zhao, Z., 2019. Processing trade, foreign outsourcing and carbon emissions in China. Structural Change and Economic Dynamics, 49, pp.1-12.

- see EU Renewable Energy Directive II, L 328/97 (point 102), ‘… harvesting in forests is carried out in a sustainable manner in forests where regeneration is ensured …’

- EU Renewable Energy Directive II, L 328/131-132, Article 29, par. 6-9

- Woodall, C. et al. (2015). The U.S. Forest Carbon Accounting Framework: Stocks and Stock Change, 1990-2016. USDA Forest Service, Newtown Square, PA. https://www.fs.fed.us/nrs/pubs/gtr/gtr_nrs154.pdf [November 28, 2019].

- Dale, V. et al. (2017). Status and prospects for renewable energy using wood pellets from the southeastern United States. GCB Bioenergy (2017)

- or up to 25 g CO2/MJ when fossil fuel is used for drying, which is uncommon in modern pellet plants.

- J. Giuntoli, A. Agostini, R. Edwards, L. Marelli, 2015. Solid and gaseous bioenergy pathways: input values and GHG emissions. JRC Report EUR 27215 EN.; Jonker, J.G.G., Junginger, M. and Faaij, A., 2014. Carbon payback period and carbon offset parity point of wood pellet production in the South-eastern United States. Global Change Biology Bioenergy, 6(4), pp.371-389.

- IPCC, 2018: Summary for Policymakers. In: Global Warming of 1.5°C. An IPCC Special Report on the impacts of global warming of 1.5°C above pre-industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change, sustainable development, and efforts to eradicate poverty [Masson-Delmotte, V., P. Zhai, H.-O. Pörtner, D. Roberts, J. Skea, P.R. Shukla, A. Pirani, W. Moufouma-Okia, C. Péan, R. Pidcock, S. Connors, J.B.R. Matthews, Y. Chen, X. Zhou, M.I. Gomis, E. Lonnoy, T. Maycock, M. Tignor, and T. Waterfield (eds.)]. World Meteorological Organization, Geneva, Switzerland, 32 pp. https://www.ipcc.ch/sr15/chapter/spm/

- For example, the Montréal Process (https://www.montrealprocess.org/) countries contain 90% of the world’s temperate and boreal forests and produce 49% of the world’s roundwood.

- Enviva’s website identifies that 17% of feedstock is mill residues, with the remainder being forest biomass. This forest biomass is not high-value timber, but rather a mix of thinnings, limbs and low-quality stems, consistent with the biomass sources identified by Matthews et al. (2018) as having low risk, and leading to low GHG emissions.