Faktabladet är enbart tillgängligt på engelska.

HVO (Hydrotreated Vegetable Oil) is a renewable diesel fuel that can be produced from a wide array of oils and fats. Initially, HVO was produced only from vegetable oil, hence the V in HVO. Today, HVO is often used collectively for these biogenic hydrocarbon-based renewable biofuels. HVO is free of aromatics and sulfur and has a high cetane number. It is a so-called drop-in fuel, meaning that it is chemically equivalent to a corresponding fossil fuel and can be used in existing diesel engines without technical blend-walls. One challenge that the production of HVO is facing is to find enough suitable and sustainable feedstock.

Primary area of use

HVO is an attractive alternative fuel since it is chemically equivalent to petroleum diesel and can be used in diesel engines without the blend walls or modifications required for e.g. biodiesel [1] (i.e. FAME). However, Swedish and European diesel standards (SS 155435:2022 and SS-EN 590:2022) limit the HVO blend due to density differences and the use of 100% HVO must be approved by the vehicle manufacturer (Mobility Sweden 2024). HVO, then mostly referred to as HEFA [2], can also be used for biojet fuel in a blend with petroleum fuels of up to 50% (IATA n.d.).

The properties of HVO in cold weather may vary, but with the right production process, good cold properties can be obtained (Drivkraft Sverige 2023).

Distribution systems

HVO is a liquid fuel and often distributed as blends in fossil diesel that are sold at the fuel companies’ filling stations. Since HVO can be blended with fossil diesel, investments in new transport or distribution system are not necessary.

There are a number of HVO and fossil diesel blends available on the Swedish market, such as Evolution Diesel (Preem), GoEasy Diesel (OKQ8), CityDiesel (St1) and Miles Diesel (CircleK). Pure HVO products are also being introduced on the market, such as the Neste MY Förnybar Diesel (OKQ8), Preem Redefine and HVO100 from St1 and CircleK. The Swedish reduction quota system has contributed to the growth of the market for HVO in Sweden.

Since 2021, the Swedish reduction quota system stipulates that jet fuel suppliers are required to provide biojet blended fuel for tanking in Sweden, thereby decreasing the greenhouse gas emissions by 27% per energy quantity up to 2030.

Feedstock and production

HVO can be produced from many kinds of oils and fats, mostly vegetable but also from other renewable sources. This includes triglycerides and fatty acids from vegetable oils (e.g. rapeseed, soybean, and corn oil), tall oil (a co-product from the pulp and paper industry) and animal fats.

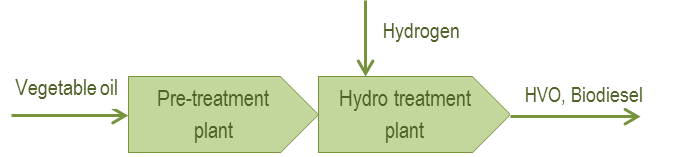

The simplified production process of HVO from vegetable oil.

HVO is produced through the hydrotreatment of oils, in which the oils (triglycerides) react with hydrogen under high pressure to remove oxygen. The hydrocarbon chains produced are chemically equivalent to petroleum diesel fuel. Propane is typically produced as a by-product. Investment costs to produce HVO are much larger than those for biodiesel (i.e. FAME) which necessitates larger plants to make the production of HVO competitive.

Through isomerization, the properties of the HVO in cold climate can be improved. Production may be carried out in stand-alone plants, producing only HVO, or in integrated plants, where also fossil fuels are produced.

50% of the raw material for HVO used in Sweden comes from Germany, Spain, France, the Netherlands, Great Britain and Sweden, while 50% is imported from other countries. It consists mainly of animal fat (slaughterhouse wastes, fish processing waste, 76%), used cooking oil (12%) and crude tall oil (7%) (Energimyndigheten 2023). Globally, vegetable oil, palm oil and rest products from palm oil production (PFAD, Palm Fatty Acid Distillate) are used to a larger extent. Pyrolysis oil has recently been introduced as a new raw material in limited quantities (f3 2025).

All HVO imported to the European Union must fulfill the sustainability criteria set out in the Renewable Energy Directive (RED). RED sets sustainability criteria for biofuels and bioliquids identical to the Fuel Quality Directive. Availability of sustainable feedstock can be a limiting factor for HVO production, as many raw materials occur in limited amounts that have competing application areas. Furthermore, in Sweden, PFAD (palm fatty acid distillate) was reclassified from waste to by-product in 2019, given its high economical value, which lead to a lower emissions’ reduction value of HVO in RED and that the use of HVO from PFAD on the Swedish market

dropped drastically.

Current production and use as fuel

The amounts of HVO sold in Sweden have increased almost steadily from about 45 million liters in 2011 to about 1 600 million liters in 2023 (Energimyndigheten 2025). The implementation of the greenhouse gas reduction quota in 2018, which stipulates certain percentages of biofuels to be blended in diesel and gasoline, has strongly contributed to this development. In 2023, the Riksdag lowered these percentages, which created a significant cut in the, until then, growing shares of biofuels in conventional fuels, from about 27% in 2023 to about 13% in 2024. In 2024, biofuels were mainly used outside the reduction quotas, and the deliveries of HVO100, a fuel consisting of 98% HVO or more, were higher in 2024 than when the reduction quotas were introduced (Drivkraft Sverige 2025).

In 2024, roughly 550 million liters of HVO were produced in Sweden by Preem. The company, that uses mixed oils and fats as raw material, will start producing another 900 million liters of both biogasoline and HVO in 2025 and has plans for increasing production capacity with about 2 000 million liters up to 2030. In a joint venture, St1 and SCA produce about 200 million liters of HVO and biojet in Gothenburg, Sweden, based on tall oil from three of SCA’s chemical pulp mills in Sweden (f3 2025). Globally, the installed capacity was about 16 billion liters per year in 2023. The United States was the single largest HVO-producing country, representing about

11 billion liters, while about 4 billion liters were produced in the EU and about 1.4 billion liters in China (2023) (World Bioenergy Association 2024). Neste Oil is the largest HVO producer in the world. Neste Oil uses vegetable oils, wastes and residues as feedstock and production takes place in Singapore, Europe, and the USA (IEA Bioenergy 2020).

Future developments

In 2022 biofuels represented over 3.5% of global transport energy demand, mainly for road transport (IEA 2025). IEA predicts total biofuel demand to increase with 23% to 200 billion liters by 2028, with renewable diesel and ethanol accounting for two thirds of this growth. Most new biofuel demand comes from emerging economies, especially Brazil, Indonesia and India. Accelerating renewable diesel production will require quicker deployment of processing technologies that can make use of wastes and residues, and innovative agricultural practices to produce plant feedstocks that do not compete with food or feed production (IEA 2024).

[1] Renewable diesel and biodiesel are not the same fuel. The term renewable diesel is used for renewable diesel fuel that is chemically equivalent to fossil diesel (such as HVO), and is described in this document, while biodiesel or FAME is described in another fact sheet.

[2] The term HEFA, Hydroprocessed Esters and Fatty Acids, is also used in parallel to HVO.

Ladda ned faktablad

HVO - Hydroprocessed Esters and Fatty AcidsEgenskaper

Chemical formula: CnH2n+2 (General formula of straight chain paraffinic hydrocarbons)

Heating value: 44 MJ/kg

Density at 15°C 1,013 bar: 775-785 kg/m³

Cetane number: >70